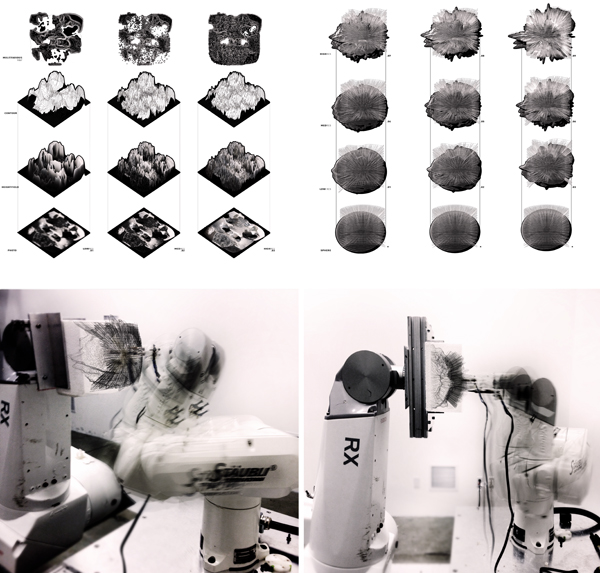

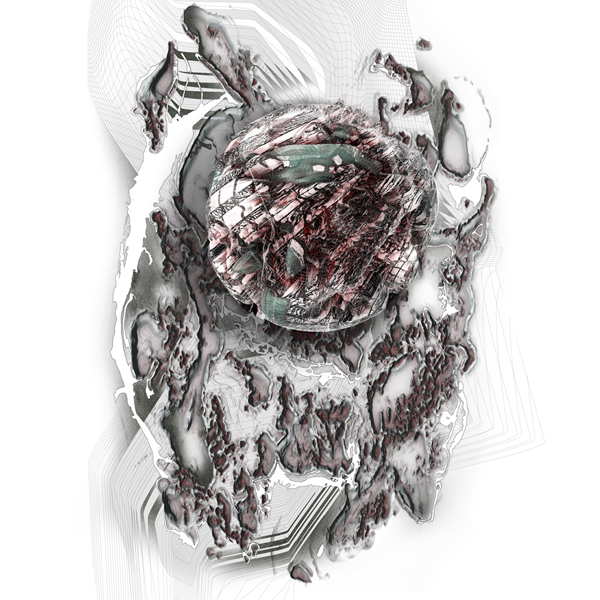

Multifarious formations is is a set of ongoing experiments in fabrication and modelling done by Daniel Caven, at the Southern California Institute of Architecture Robotics lab. The research constructed takes on the dilemmas of computer based modeling- and its lack of understanding of material agency within simulation and transformation.The idealistic setup for architecture, fabrication, and simulation is to have a real time feedback loops allowing the designer/machine to update according to gesture and errors in simulation. This allows for fabrication to have a customization and idealism to the processes. Using scanning methods and data analysis in the digital world the project is going to take on the idea of smart tooling.

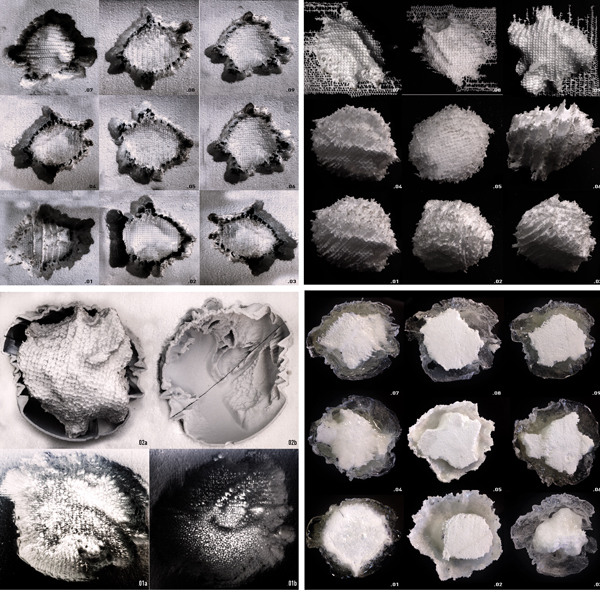

Tactics in fabrications have been based on patterns and dialogs upon G code generation limiting uniqueness to a manufacturing process. Using paths in the milling process gives a diminishing value in design and a declining appreciation for uniqueness in design. Advanced fabrication in the research and experimentation takes on new ways of producing objects each unique to one another.

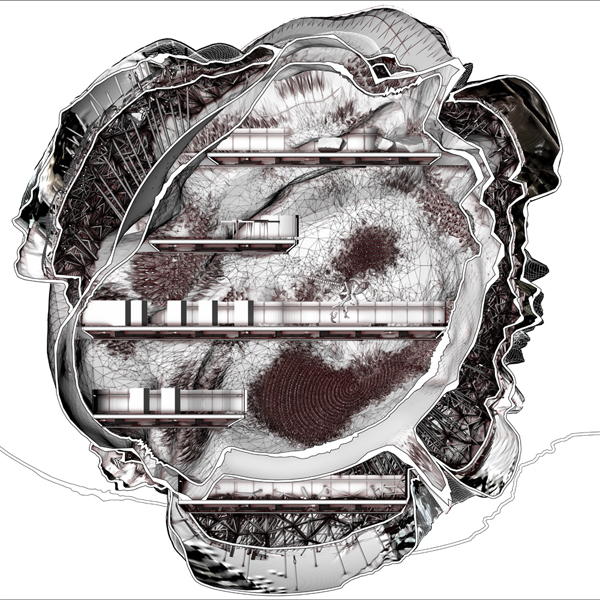

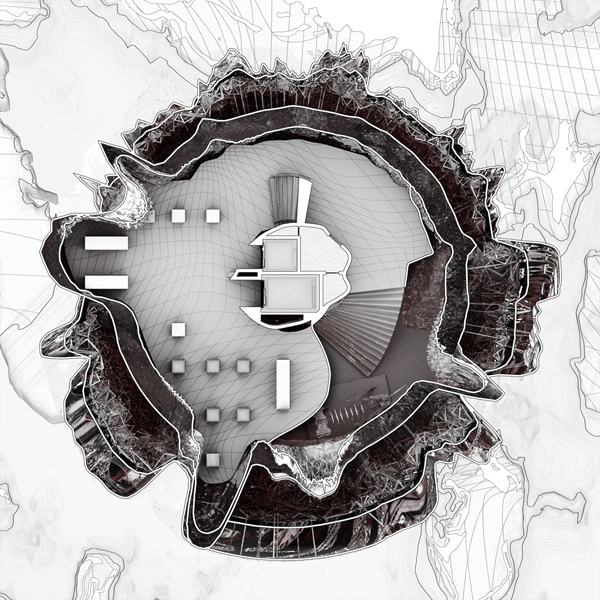

Image based drawing sets that change in resolution parameters allows for robotics to take on true free form fabrication. Image based manufacturing gives the result of the object at different resolutions and sets up new ways of making through single object displacement maps. Using this technique in its beta stage this research is able to create many different variations of the same object and a real time loop by bring the object back into the computer to show end results. Architecturally it deals with a precise imprecise way of developing analog modeling and digital feedback loops. Height Field maps are used as tool paths for building and forming objects that are then encased in resin and then removed my acid washes.

Multifarious Formations seeks to combine methods of computer based modeling and analog modeling. The research seeks to create a platform for freeform fabrication and real time feedback. In order to attack multiple problems of tooling, perform, shaping forces, and material intelligence.