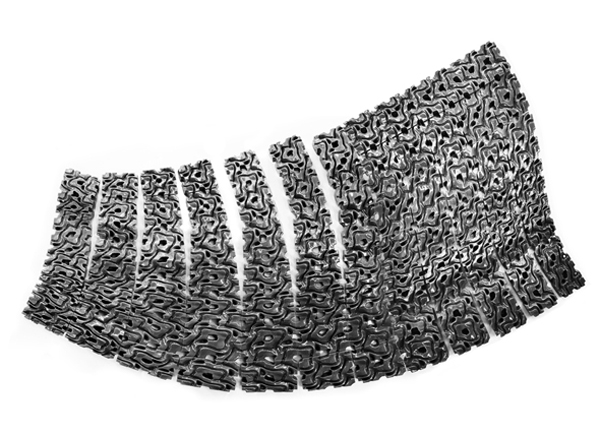

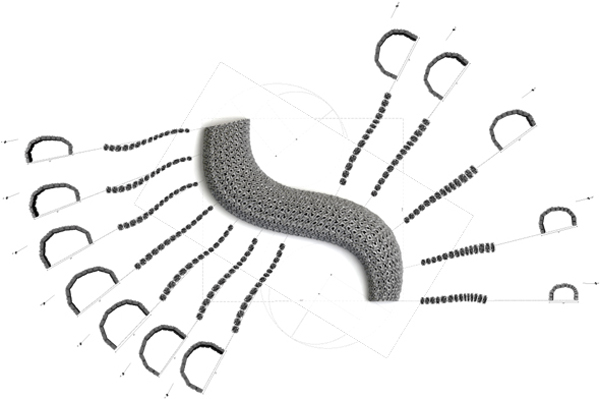

The promise of 3d printing for usable mass consumed objects seem to have been just around the corner for nearly a decade now. A new formulation cement-based polymer developed by Rael San Fratello Architects in partnership with the University of Washington and University of California Berkeley replaces more expensive powder mediums for large scale objects. The prototype SeatSlug bench is a demonstration project of the potential of the material and 3d printing process to make sophisticated large pieces using low cost, non repetitive objects. The bench is comprised of 230 individual pieces, each developed as a unique shape. The cement based polymer has a compression strength of 4700 pounds but cost up to 90% less than conventional fusible powders. Rapid 3d printing technologies have been traditionally used to create relatively expensive prototypes for industrial design or more recently small scale objects with low cost devices.

The SeatSlug is based on the shape of the recently discovered flabellina goddardi sea slug and surface inspired by karakusamon patterns, traditional Japanese designs. The unique shape is both functional and collectable with its provocative massing and highly polished finish, possibly with an eye to be built individually for higher end furniture stores or galleries. The manufacture of large scale merchandise as low cost printed objects with hand assembly near the end user addresses the issues of scale and cost of high quality products, which are often not available to market due to restraints in supply and demand.